Published 5th May 2025

Common Challenges with PVC Free Vinyl and How to Overcome Them

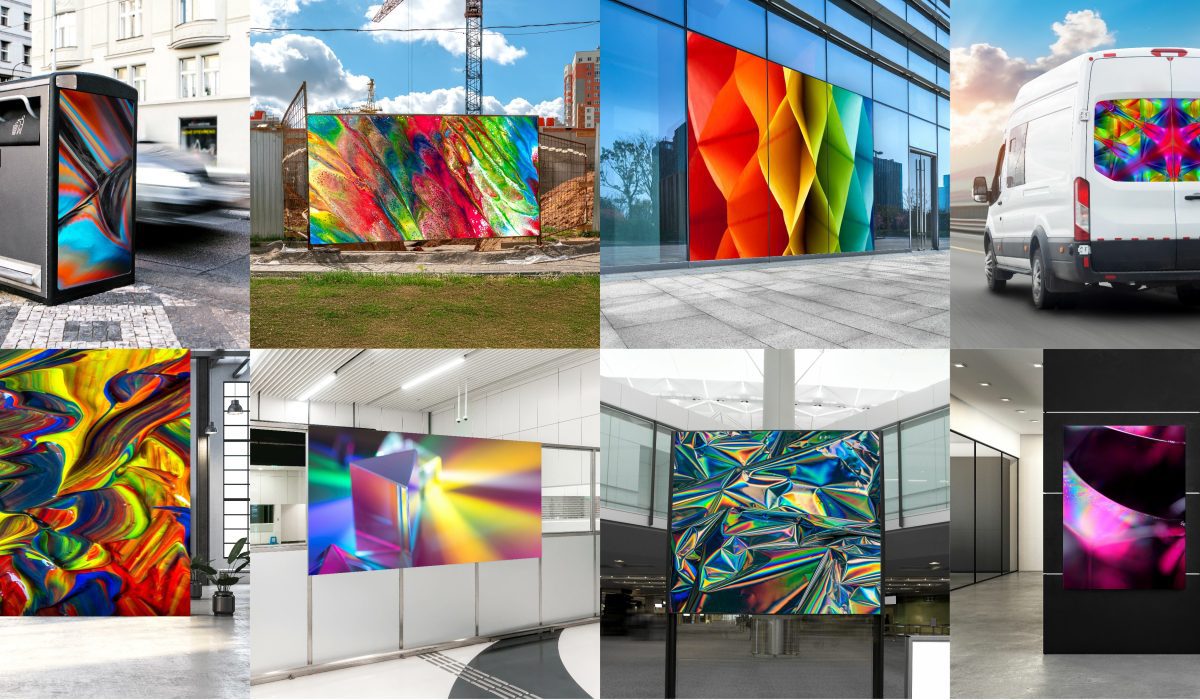

PVC free vinyl is becoming an increasingly popular choice for businesses looking to reduce their environmental impact without sacrificing quality in their print materials. However, as with any emerging technology, there are questions around whether eco friendly printing solutions are suitable replacements. Transitioning to PVC-free alternatives raises concerns over whether print quality and durability will be maintained, as well as compatibility. Today, we discuss some of the common challenges that PVC free vinyl substrates may present and solutions to those issues.

The Behaviour of the Material During Printing

The Issue:

PVC-free vinyl alternatives do not have the same ‘memory’ as PVC because they behave differently under heat and stress. In this case, the memory of the material refers to its ability to return to its original shape after being subjected to an external stressor like the printing process. This can cause issues with the material deforming during print and can result in a poor-quality finish.

The Solution:

To ensure that quality is unaffected when switching to PVC-free materials, some changes may be needed to your production process. Ensure your machinery is set up correctly for the material and that there is no unnecessary external stress being placed on the material. Minimise heat exposure where possible, both during printing and curing. This will help to ensure that final print quality remains as high as it is with traditional PVC.

PVC Alternatives Have Higher Shrinkage Rates

The Issue:

When exposed to external factors such as sunlight (UV), heat and temperature changes, vinyl can be subject to post-application shrinkage. PVC vinyl has a low shrinkage rate, usually only around 2% at the most over time. Polyethylene (PE) and polypropylene (PP) have much higher shrinkage rates, often between 4-10% dependent on the application environment, thickness of the material and the type of adhesive backing.

The Solution:

PP and PE vinyls need to be treated with a little more care during application than PVC. Once installed, they are great, eco-friendly alternatives that offer similar levels of performance in most cases but it is important to be aware of their limitation and do what you can to manage those.

Pairing the vinyl with an eco-friendly laminating film is a great way to help protect the vinyl and minimise the amount of shrinkage over time once it has been applied. This is especially important in outdoor or high traffic conditions where exposure to adverse elements such as heat and UV light will be greater.

Something else to consider with all substrates, but with PVC-free vinyl in particular, is the process of outgassing. Solvent and eco-solvent based inks are more prone to outgassing than other types, and the amount of ink used will also affect the process and how long it takes. Ensure the print has sufficient drying time before cutting or lamination to allow the outgassing process to occur. A good guideline time for this is around 24 hours.

Finally, allow for the potential shrinkage of the substrate during printing and installation. Leave a sufficient gap at the edge of a design (much as you would with bleed lines for CMYK print) and, when installing, consider using additional edge capping around the border of the vinyl. Ensuring adequate coverage of the vinyl’s edges when installing means the shrinkage can effectively be covered. It is important to discuss this with the client and installer at the outset.

Weaker Adhesive Bond

The Issue:

PP and PE films have a weaker bond than PVC between the film and the adhesive. This means that the adhesive is more likely to stay on the surface the film is applied to after removal and so additional preparation may be required when the print is being replaced.

The Solution:

This issue is more likely to affect the installers of PVC free materials than anyone else. As such, installers should be aware of this and the additional time that installation of a new print may take. Extra time should therefore be factored into quotes for fitting and this should be made clear to the client.

Issues When Cutting and Weeding

The Issue:

Whilst PVC cuts cleanly with traditional plotters and blades, eco-friendly alternatives may not. PP based vinyls and films are more brittle than PVC and PE is more prone to stretching. This can cause issues during cutting and weeding (the removal of excess material that is not part of the final design) which can result in the print being damaged.

The Solution:

Sometimes, these problems can be avoided by simply adjusting cutting speed. It is wise to use shaper blades when cutting PVC free films too, as this will further minimise the risk of the print being damaged. Finally, be sure to test all settings on a sample print before commencing full production. Getting the setup right is crucial before committing to a full print run, and doing so will ensure maximum profitability from each job.

Limited Availability and Product Selection

The Issue

Because PVC free vinyl is still an evolving and relatively new market, it can sometimes be challenging to source the exact product specifications needed for some applications.

The Solution:

Partnering with a specialised supplier, such as ourselves, ensures you always have access to a wide range of PVC free materials tailored to different applications. Keeping an open line of communication with your suppliers can also provide insights into upcoming product developments and custom solutions.

Our Thoughts on PVC Free Vinyl

While making the switch to PVC free vinyl presents challenges, there are always solutions and they are quite manageable. By working with a reliable and knowledgeable supplier, using high-quality materials and ensuring print compatibility, you can confidently adopt eco-friendly print solutions without compromising on performance.

To find out more about PVC-free print alternatives, browse our range and read some of the other useful guides on the Innotech website. Discover the different types of PVC-free material or read our complete guide to PVC-free vinyl. Our site contains a wealth of knowledge on eco-friendly print materials and all manner of other print related subjects!

Are you considering going PVC free in your print business? Speak to our sales team today. We offer free samples on most of our materials to help you make an informed decision before ordering and are always happy to offer discounts on bulk orders.

Latest blog posts

View all posts

16th January 2026

Cold Weather Vinyl Installations: Do’s, Don’ts & Best Practice

Brrrrrrrr… It’s still cold outside! Cold weather can significantly impact vinyl performance if best [...]

15th April 2025

Innotech Expands Range of General Formulation Self-Adhesive Vinyls

After becoming the exclusive UK distributor for General Formulations last year, Innotech are now offering the new GF [...]

11th April 2025

Gary from Print.com is Pets in Print Trophy winner

Innotech Digital and Display announce the winner of this year’s Pets in Print competition is Gary from Print.com. He [...]