Published 24th Jun 2021

The Future’s White! Clear Vinyls & Films and White Ink Technologies

Clear Vinyls & Films and White Ink Technologies

The effective use of white ink in wide format printing, especially on clear vinyls & films is something that machine, media and ink manufacturers have been working hard towards for many years. White is a bit of an anomaly in the ink world. It can add something special, but it has always come with difficulties that have hindered its widespread use.

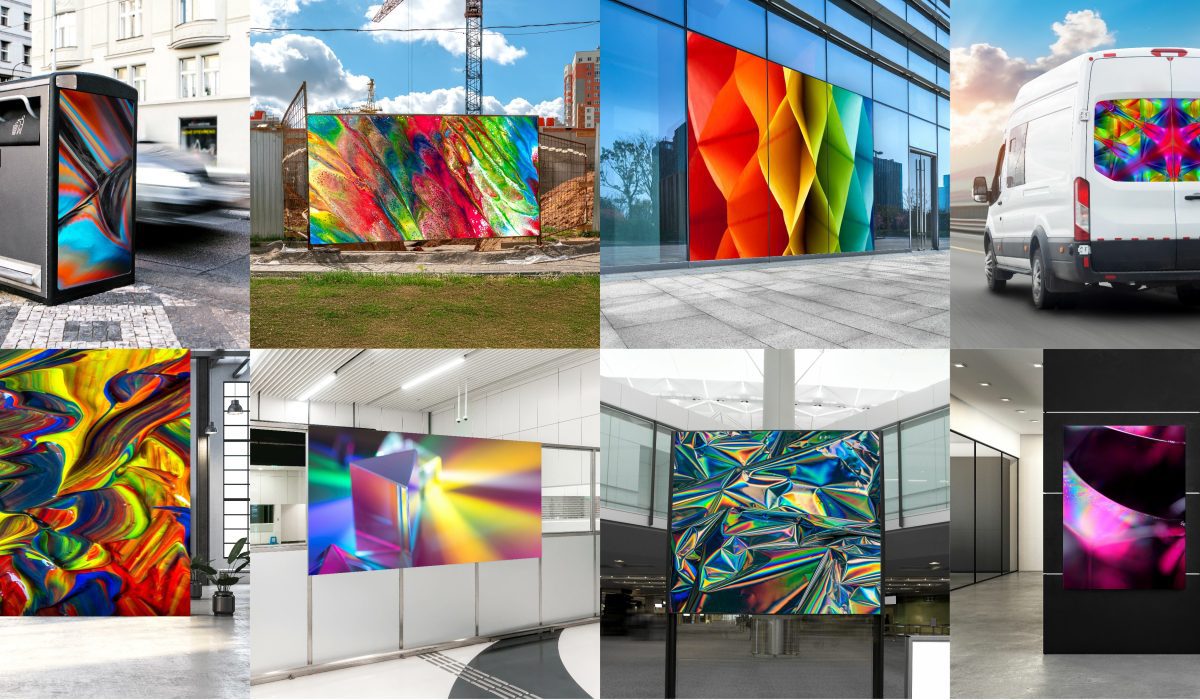

Unlike all other CMYK inks, a properly designed white ink is fully opaque and this means it offers a sharper image quality that enables a host of startlingly good effects. It can be used in many ways and combination with other inks and types of media to create many different styles that can be highly personalised and very striking. This has always made it of real interest to print providers, designers and brand owners.

Used effectively, white ink provides clearer prints because it can create much more accurate image outlines. This can be on coloured media and film, but can also be used on white media by being laid on top of other colours. Its opacity means it contrasts better with other colours and can create effects that no other colour can achieve.

Modern white inks are also as flexible as coloured inks, making it ideal for use with a range of products that may need to be stretched or folded around objects. Print materials like General Formulations 287 RoughMark which is a clear, conformable vinyl that is designed for application to rough services, such as brickwork. Other clear vinyls & films that benefit significantly from white ink are static cling materials and optically clear vinyls..

White ink on a coloured media or Clear vinyls & films delivers the most vibrant of contrasts and is highly sought after in the display world.

Getting the right chemistry

Unfortunately, all these benefits come with a very loud warning. Yes, white ink helps provides fantastic images, but it has always come at a cost.

You probably have at least one old tin of white paint in your garage. If you do, go and have a look at it later. You will see that it has separated. For best opacity, the pigments in white ink need to be three times larger and have twice as many pigments as coloured ink. But this also means they separate and settle more quickly. They can’t help it – that’s just the way gravity works! With coloured paint, a quick stir will restore the product to its useable state, but this is almost impossible to do with white. The white ink pigments are just too large to be restored back into its useable form, no matter how much you stir it with a stick. Once the genie is out of the bottle so to speak, you can’t get it back in.

This is what happens in your wide format printer. Not only can the large pigments in high concentrations quickly clog up the tiny print nozzles, but the ink itself starts to separate very quickly if left unused for any length of time. The nozzles require regular cleaning and the ink itself can separate or fall out of solution. For most people, the payoff between great prints with white ink and the unreliability of the printer because of it, is not a commercially viable one.

Innotech print materials have long been printed on HP machines, a leading printer and ink manufacturer. We spoke to HP’s Chief Inkologist, Thom Brown about their launch of the new HP Latex 700 and 800 Printer Series, and how HP has sought to solve the white ink issue.

“Allowing our customers to enjoy all the benefits of white ink, without impacting the effectiveness of the printer has been a big challenge for us that we have been determined to resolve. We are delighted to say that the latest printer series has definitely achieved this objective. We looked at the problem and could see the two main issues were ensuring printhead reliability and being able to keep the white ink pigments properly mixed in the solution,” he says.

Brown continues, “We have developed some pretty clever chemistry in our inks. Without it, the pigments get pulled easily to the bottom of tubes and cartridges etc and can’t be restored, even by stirring. Even at a microscopic nozzle level, the white ink pigments get separated. We saw the answer as being to make the sediment created by the white ink one that could be more easily restored to a working solution. We have added a magic ingredient to our water-based latex ink that helps create a ‘soft sediment’. This soft sediment is officially called a weakly flocculating gel, and in this form, a quick stir returns the white ink to a useable print solution.”

The major development in the new HP Latex printers is in how it circulates the ink. The whole tubing system from the cartridges to the nozzles is being continuously circulated. “We don’t give the ink a chance to settle,” says Brown. “And even when it gets to the printhead, we have designed it so that at the microscopic nozzle level, the nozzles themselves are used to keep the ink circulating. It is a tiny plumbing system that allow the nozzles to fire in a circle and keep the ink moving. The result is the whitest of whites that does not clog up the system or cause any other issues.”

Another issue has been that most print providers do not need white ink all day every day. This means the white ink cartridge in its dormant form will quickly succumb to separation and often ends up having to be wasted. “With HP Latex printers, you can quickly and easily swap printheads in and out. We have created a storage wheel on the printer that you connect to the white ink unit and this is regularly turned every 45 minutes to ensure the solution doesn’t separate. Simple!”

This new formulation of white ink in the HP 700 and 800 Latex Series works brilliantly with a range of Innotech media. You can find some of our products being tested on this video:

Here at Innotech we are really excited by the developments HP has made with Latex because we know how amazing white ink looks on our media.

If you would like to find out more about how white ink can increase business and customer satisfaction for your company, please contact us now for some samples.

GET IN TOUCH >

Latest blog posts

View all posts

15th April 2025

Innotech Expands Range of General Formulation Self-Adhesive Vinyls

After becoming the exclusive UK distributor for General Formulations last year, Innotech are now offering the new GF [...]

11th April 2025

Gary from Print.com is Pets in Print Trophy winner

Innotech Digital and Display announce the winner of this year’s Pets in Print competition is Gary from Print.com. He [...]

2nd April 2025

#RollOnTheDough

If you dough, you dough… 🍩 Back again to sweeten up your April! We’re giving you the opportunity to win [...]