Published 29th Nov 2023

How to Print on Magnet – Tips for Optimising Print Quality

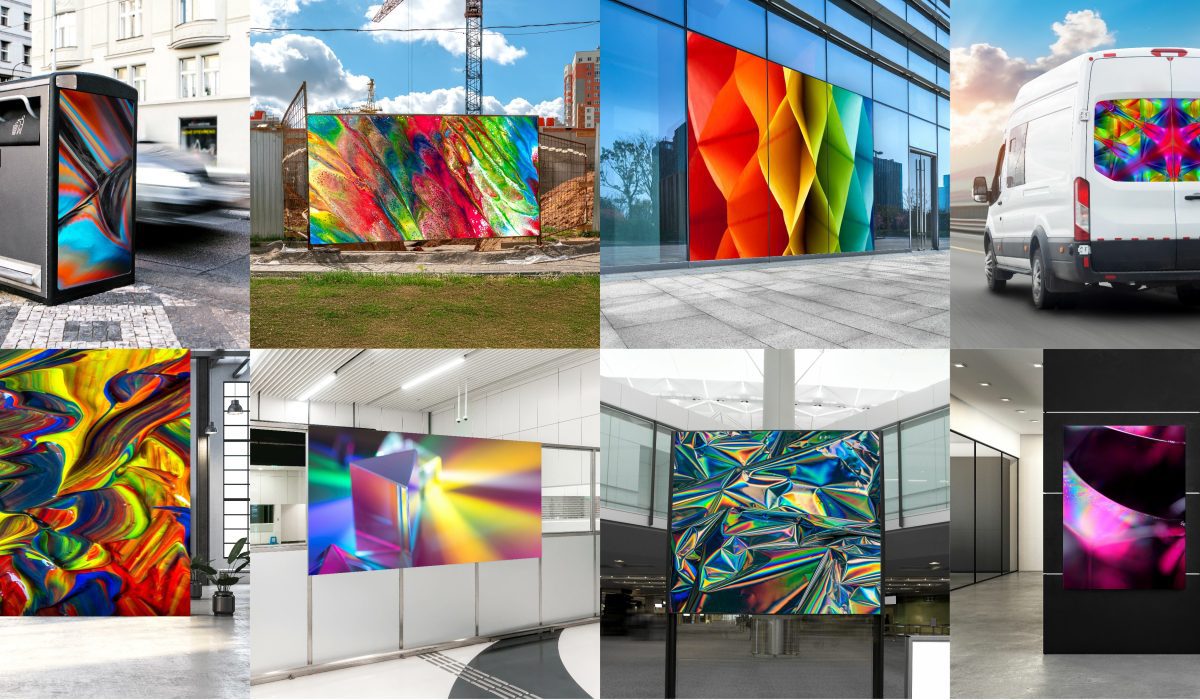

Printing on magnet opens a world of possibilities for creative applications, from fridge magnets to retail instore graphics.

However, working with magnetic materials comes with challenges that require specialised techniques to achieve professional-quality results. Here’s some key considerations for working with magnetic materials.

Choosing the right magnets

Not all magnet sheets are created equal in print quality – flexible magnetic sheets that can bend and curve are generally best, rather than using rigid sheets.

Look for magnet thicknesses between 300mic and 1000mic for optimal flexibility without warping. Vinyl-coated magnet sheets such as Kinetix MS300, MS600 or MS850 are designed for inkjet printing and are best for rich colour reproduction. The printable coating also creates a smooth, consistent surface that prevents ink from bleeding or feathering.

Printing on magnet opens a world of possibilities for creative applications, from fridge magnets to retail instore graphics.

However, working with magnetic materials comes with challenges that require specialised techniques to achieve professional-quality results. Here’s some key considerations for working with magnetic materials.

Proper printer & ink selection

Solvent, latex or UV-C inkjet printers are versatile for almost all types of magnetic media. Unlike dye-based inks, pigment solvent inks are specifically engineered to bond directly to the vinyl and polyester coatings on magnet sheets.

This bonding eliminates the need for a primer or overcoat to make the inks adhere correctly, speeding up print times. Choose a printer like the Roland TrueVis, HP Latex or Mimaki UJF that accommodates flexible and thin magnetic substrates for best results.

Another critical factor with the printer is the transport path. When it comes to printing magnets, having a non-ferrous transport path is essential for the media to feed through the printer evenly and avoiding horizontal banding.

Colour management is critical

To achieve accurate colours that match your digital design, printer colour management is essential. Create custom ICC colour profiles for the specific magnet media you use with printing colour calibration charts – this will characterise how the printer, inks and magnet sheet interact to reproduce colour.

With a correct ICC profile loaded in your printing software, the colours you see on the screen will closely match the printed output. Re-calibrate the profile if you switch magnet materials from different manufacturers for the best results.

Finding the optimal print settings

Some trial and error is expected when dialling in the best print mode for magnets. Necessary settings that impact print quality include print resolution, ink densities, number of passes, curing temperature and media thickness.

Start with the media manufacturer’s suggested settings, then fine-tune from there. Too much ink can cause bleeding or wet ink to stick during the lamination stage if over-saturated, so find the sweet spot for vibrant colour without compromising crispness.

Lamination and finishing

It’s always good practise to laminate the magnets to protect against scratching and moisture for maximum durability of prints.

Hot roll and cold roll laminators are standard for high-volume production, and for short runs and prototypes, self-adhesive laminate sheets provide good protection without the need for significant equipment investment.

Allow printed magnets to fully cure before laminating so the inks are bonded tight to the surface, usually 24 hours minimum. Proper finishing transforms your printed magnet from an amateur project into a professional-grade product ready for sale and distribution.

Need more help printing on magnet?

Browse our range of magnetic and ferrous vinyl and feel free to contact us anytime if you have any questions or need help printing on magnets.

Latest blog posts

View all posts

16th January 2026

Cold Weather Vinyl Installations: Do’s, Don’ts & Best Practice

Brrrrrrrr… It’s still cold outside! Cold weather can significantly impact vinyl performance if best [...]

5th May 2025

Common Challenges with PVC Free Vinyl and How to Overcome Them

PVC free vinyl is becoming an increasingly popular choice for businesses looking to reduce their environmental impact [...]

15th April 2025

Innotech Expands Range of General Formulation Self-Adhesive Vinyls

After becoming the exclusive UK distributor for General Formulations last year, Innotech are now offering the new GF [...]