Published 19th Jan 2024

Magnetic Receptive Surfaces 101: How Ferrous Materials Hold Printed Magnet

Walk through a supermarket or retail store, and you’ll notice colourful signage and displays stuck to metal shelves and fixtures. Peer closer, and you’ll find these visuals are attracted to the metal surfaces, mounted not with tape, adhesive backing, or nails but with an unseen magnetic force.

This almost magical adhesive ability comes from print receptive magnetic materials.

What makes printed magnet work?

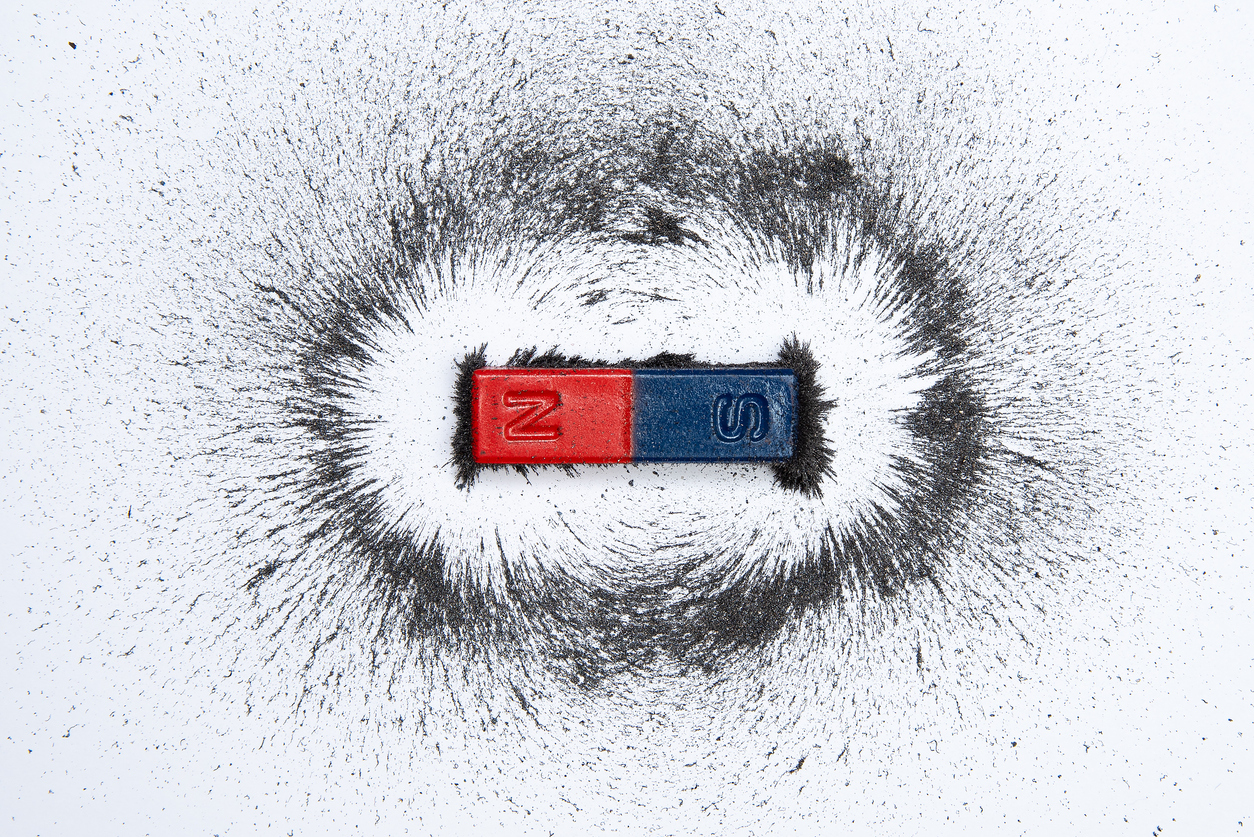

Printed magnet displays require two key components: a ferrous material that is magnetically receptive and a printable magnetic sheet or material coated on the back with a magnetic receptive layer.

Ferrous materials like steel and other iron alloys contain iron that enables magnetism. When the poles of a magnet attract and stick to a steel surface, it demonstrates this magnetically receptive property.

Magnetic sheets and materials have a layer that contains magnetic properties, so the sheet itself sticks when magnets on the other side make contact, with this magnetic attraction forming the bond that allows magnetic printing to adhere to metal – no adhesive required.

Common applications

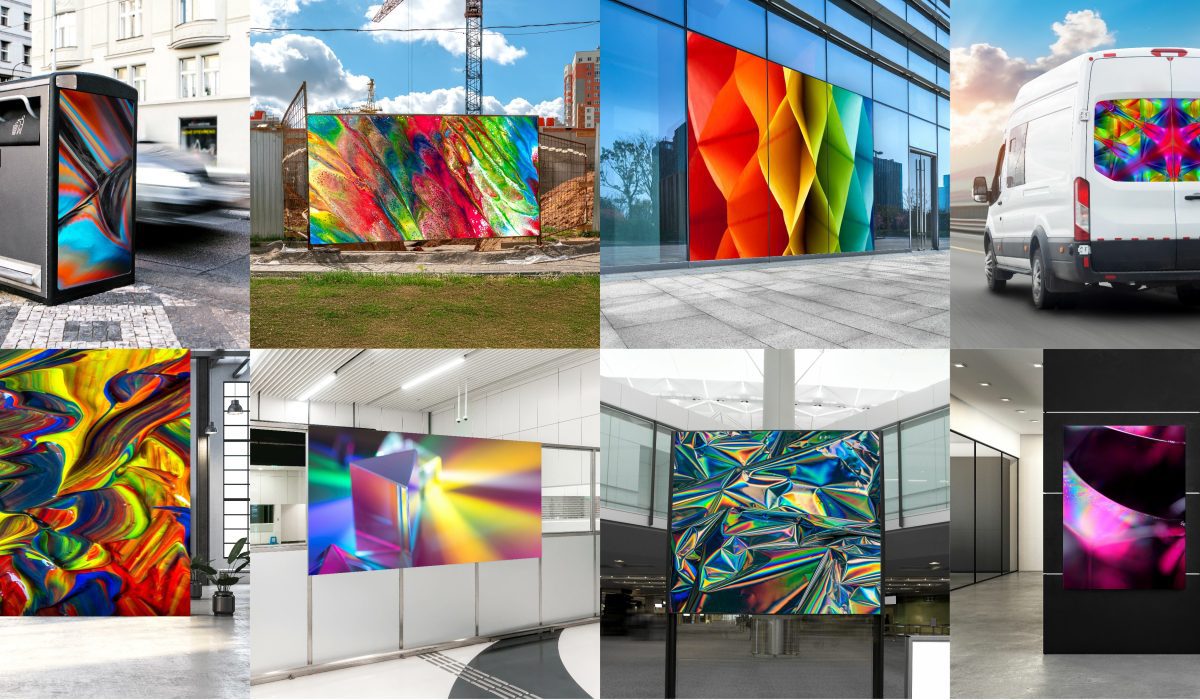

Every magnetic receptive surface is compatible with a magnet, letting us print signs, artwork, maps, and anything else with fantastic adhering qualities.

The beauty of magnetic printable materials is they leave no residue after installation and are reusable, making them perfect for temporary use.

We regularly see them in:

Retail displays

One of the most popular uses for magnetic printing is retail displays, where shopping centres and big stores attach promotional signage and messaging to steel shelving, refrigeration units, and other fixtures. The ability to quickly switch out marketing material makes magnetic printing ideal for seasonal retail promotions

Product stands

Many brands use printable magnetic sheets to showcase new items, from trade show booths to countertop product displays. The lightweight material easily sticks to metal display stands yet peels off cleanly afterwards, allowing for reusable graphics on product stands that can showcase anything a company offers.

Signage

Indoor and outdoor business signage often relies on steel bases or frames. Magnetic receptive coatings let these metal signboards feature replaceable printed messaging that can be updated anytime. Outdoor signage, in particular, benefits from the durability of materials intended for harsh weather and UV exposure.

Insights on printable magnetic media

When specifying magnetic printing for your project:

- Ensure the sheet thickness doesn’t exceed your printer’s maximum capability. Most professional wide-format inkjet printers handle sheeting up to 0.85mm thick.

- Choose weatherproof, UV-resistant magnetic materials for outdoor signage that will face environmental exposure.

- Choose sheets and rolls with strong adhesive coatings, so magnets affix securely, preventing unexpected detachment.

- Print with wide format printable magnetic sheets over 760mm wide for large, eye-catching display graphics.

- You can usually print magnetic sheet with eco-solvent, solvent, latex, or UV-C ink –you might also want to laminate for scratch resistance. This is an additional step that adds to the production time and cost.

Latest blog posts

View all posts5th May 2025

Common Challenges with PVC Free Vinyl and How to Overcome Them

PVC free vinyl is becoming an increasingly popular choice for businesses looking to reduce their environmental impact [...]

15th April 2025

Innotech Expands Range of General Formulation Self-Adhesive Vinyls

After becoming the exclusive UK distributor for General Formulations last year, Innotech are now offering the new GF [...]

11th April 2025

Gary from Print.com is Pets in Print Trophy winner

Innotech Digital and Display announce the winner of this year’s Pets in Print competition is Gary from Print.com. He [...]