Fujifilm burst into the camera film scene in 1936 with the launch of its first colour film, Agfacolor-Neu, and over the next 50 years, their photographic films, inks, and imaging solutions cemented their position among the best.

The 90s saw Fuji get its foot in the wide-format printing door with the imagePrograf printer and imagePRESS digital production presses for flexible and rigid media, with a digital turning point in 2008 with the unveiling of the Océ Arizona 550 GT – Fujifilm’s pioneering UV flatbed printer partly borne from their acquisition of Océ.

More recently, they launched the Iridesse Production Press—the industry’s first six-colour, single-pass print engine capable of metallic tones—and the award-winning UVgel roll-to-roll Colorado printers, which use LED-curing gel inks.

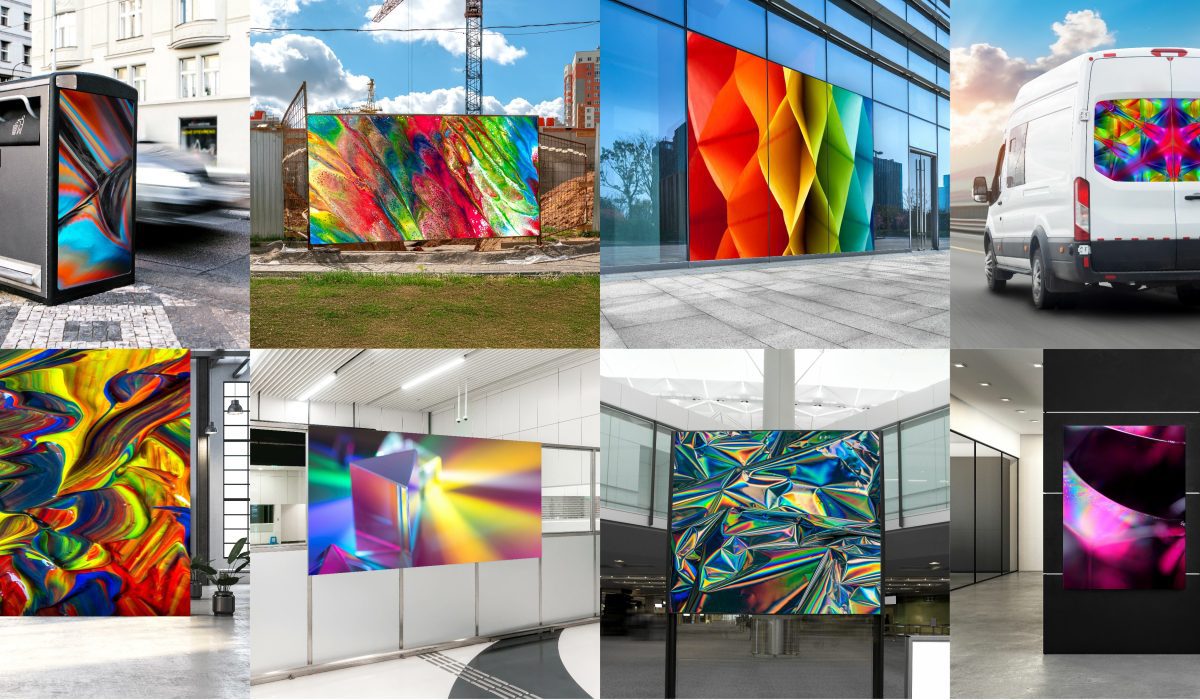

Today, Fujifilm’s comprehensive portfolio spans high-productivity flatbed, hybrid, and roll-to-roll inkjet systems renowned for vibrant colours and precision quality.

Printer range

The Acuity Prime, Ultra, and Ultra Hybrid systems with the Uvijet Ink System make up Fujifilm’s industrial printer range.

The Ultra Hybrid is Fuji’s top-end printer line. It prints LED-curing ink for rigid and flexible media with a 3.3m platform and achieves near-photographic quality on POP, banners, vinyl, and cardboard display materials.

Acuity printers include the mid-range UV LED Prime Hybrid and the standard Acuity Prime, a flatbed with a 2.5 x 1.25 m print capacity.

Fuji’s largest printer is the Ultra R2, which supports print media up to 5.13 m – a super-wide format among the widest in the industry.

Fujifilm Acuity Ultra R2 Series

The Acuity Ultra R2 series offers the perfect ratio of quality, speed and cost-in-use to profitably produce a massive range of indoor and outdoor applications up to 5 metres wide.

Powered by industrial printheads with 3.5 picolitre droplets and specially formulated LED UV inks, it achieves exceptional print quality comparable to leading water-based inkjet systems – perfect for the high-end indoor display market.

Gargantuan format capabilities, multi-roll printing for boosted productivity, and compatibility across various materials make the Ultra R2 a versatile solution for everything from exhibition graphics and POS displays to fine art reproductions.

Productivity-enhancing features like the unique chilled vacuum table, onboard backlighting for quality inspection, and automated nozzle spitting system streamline workflows.

Available in 3.2m and 5m models with configurations spanning 6-colour, 6-colour+white/white, and 2xCMYK, the Ultra R2 is a powerful roll-to-roll solution for profitable super-wide printing.

Fujifilm Acuity Prime Series

The Acuity Prime flatbed platform sets new benchmarks for versatile and valuable print production across rigid and flexible media.

Its flatbed design with a dedicated five-zone vacuum system easily handles materials up to 2 inches thick and 100×50 inches wide at speeds reaching 1615 ft2/hr.

Offering excellent ROI at a cost-effective price point, Prime delivers outstanding quality via Fujifilm’s LED-cured Uvijet HM inks and Ricoh Gen 5 grayscale printheads with variable 7-21 picolitre drops.

The primer enhances adhesion and image quality on complex surfaces. Four-, five-, six-, or seven-channel colour configurations provide multiple options spanning CMYK, white, clear, and primer channels for creative and industrial applications.

Fujifilm SpyderX Series

Fujifilm’s SpyderX series combines powerful performance with incredible flexibility in a productive, reliable flatbed platform with optional roll-to-roll capability.

Designed and manufactured by Inca Digital and Fujifilm, it integrates Dimatix printheads and Uvijet UV-cured inks to deliver accurate quality at blistering speeds up to 2,476 ft2/hr across rigid and flexible substrates.

The robust 126″ chassis is available in dedicated flatbed or hybrid flatbed/roll-fed versions, allowing it to handle virtually any graphics application efficiently.

Six colours plus white produce exceptional quality using light cyan and magentas to smooth gradients. Automated features like nozzle mapping, printhead maintenance scheduling, and remote diagnostics software streamline productivity.

Key innovations include:

- The zoned vacuum bed.

- Print-a-Shim technology for consistent output across the table.

- An optional roll system for roll-to-roll or simultaneous rigid/flexible printing.

Manufacturing information

Most of Fujifilm’s large-format printers are made in Japan or China, and their Chinese facilities share the same production technologies as Japan’s. Fuji also has a manufacturing base in Greenwood, South Carolina.

Innotech supplies a complete range of wide and grand-format print materials for Fujifilm printers, including rigid and flexible display materials. Browse our complete range of digital print media here and get printing.

Latest blog posts

View all posts

16th January 2026

Cold Weather Vinyl Installations: Do’s, Don’ts & Best Practice

Brrrrrrrr… It’s still cold outside! Cold weather can significantly impact vinyl performance if best [...]

5th May 2025

Common Challenges with PVC Free Vinyl and How to Overcome Them

PVC free vinyl is becoming an increasingly popular choice for businesses looking to reduce their environmental impact [...]

15th April 2025

Innotech Expands Range of General Formulation Self-Adhesive Vinyls

After becoming the exclusive UK distributor for General Formulations last year, Innotech are now offering the new GF [...]