Agfa started as a dye manufacturer in 1867, transforming into an industry powerhouse in 1925 following its merger with IG Farben.

1936 saw Agfa’s first colour photography innovation—Agfacolor-Neu—come to market—a colour film for cameras. Twenty-three years later, Agfa launched the first fully automatic 35mm camera—the Agfa Optima.

The wide and grand-format printing side of Agfa mostly started in the 90s, first with the acquisition of Hoechst’s printing plate and proofing business and then DuPont’s Graphic Arts division just years apart.

By 1997, it was the world’s number one prepress and proofing supplier, but its foray into the sign, display and industrial printing markets would come a decade later.

In 2007, Agfa created a new department for research and development in printing to transform the large-format printing market.

Several acquisitions later—Gandi Innovations, TIP Group, Inca Digital Printers—and Agfa is now a global leader. But it’s not all about the patents and companies they bought. Much of their technological progress is fuelled from within.

Recent innovations

A top example of Agfa’s innovation is the Anapurna Ciervo H3200, a 3.2m wide hybrid UV LED inkjet printer with a continuous board feeding capacity that can print up to 4 rigid boards simultaneously for improved productivity. Its new print shuttle and engine significantly enhance productivity and print quality on both rigid and flexible materials.

Another incredible piece of kit is the high-speed, sheet-fed, water-based SpeedSet Orca 1060 inkjet, which can print 11,000 B1 sheets/hour at 1,200 dpi resolution for unbeatable speed to market and uncompromising quality.

Popular printer lines:

- Onset X HS series – High-speed flatbed UV inkjet printers up to 1450 m2/hr.

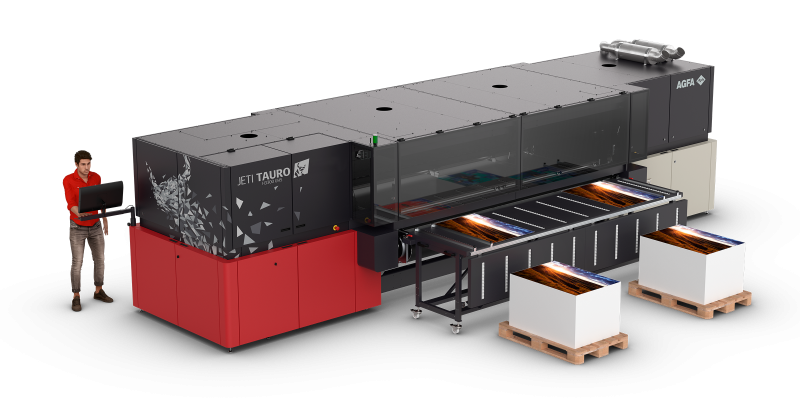

- Jeti Tauro H2500/H3300 LED – High-productivity hybrid UV LED printers for rigid and flexible digital print media.

- Jeti Mira MG LED – True flatbed UV LED printers up to 3.2m wide.

- Anapurna LED series – Wide-format hybrid UV LED printers up to 3.2m.

- Oberon RTR3300 – 3.3m roll-to-roll printer with dual-roll option.

- Avinci CX3200 – 3.2m dye-sublimation printer for soft signage.

Ink technology:

- UV LED-cured inks with wide gamut, low consumption via Thin Ink Layer technology.

- GREENGUARD Gold certified inks for safety and low emissions.

- Dye-sublimation inks for textile printing.

Agfa’s latest printers

Agfa’s flatbed, roll-to-roll, and hybrid inkjet printers for large—and grand-format printing are among the best in the industry.

Their printers stand out because they consume little energy, have an extremely wide media and application scope, and use proprietary Agfa inks that ensure the best quality.

Rigid and flexible media are no problem for Agfa printers, with hybrid inkjets delivering flawless results on sign and display materials.

Roll-to-roll inkjets brush aside the widest print jobs, while flatbed inkjets are faster at pushing out flat materials like signage.

Hybrid inkjets

At the head of Agfa’s hybrid class is the Jeti Tauro H3300. This 3.3m wide beast can rip out prints at a blistering 905 square metres per hour across a wide range of rigid or flexible media. What’s more, it’s fully upgradeable to increase that speed and add extra ink channels like white, primer and varnish down the line.

Another shoo-in for inkjet print shops is the Jeti Tauro H2500. While narrower at 2.54 m, it still manages a rapid 390 sq m/hr print speed using CMYK plus white and primer inks out of the box.

Flatbed printers

The Onset Grizzly X HS takes the crown if we’re talking flatbeds. This highly automated line can reach incredible speeds of up to 1,450 square metres per hour using up to 3 sets of CMYK inks plus lights and whites.

Another impressive flatbed is the Jeti Mira MG2732 with its vast 2.7 m x 3.2 m bed size for high-quality POP, packaging, and display graphics – it prints at a rapid 248 square metres per hour using CMYKcm plus white inks.

Roll-to-roll inkjets

The Jeti Condor RTR5200 is Agfa’s fastest and largest roller unit. It supports media 5.28 metres wide and can print at up to 672 m2/hr. You can feed in single rolls or up to three 6-inch rolls for continuous, automated printing.

The Oberon RTR3300 is no slouch, either. It can produce 3.3-metre-wide prints at 224 square metres per hour in crisp CMYK plus white or whole CMYKcm, and air-cooled UV LED lamps ensure low energy consumption.

Manufacturing information

Agfa-Gevaert has global manufacturing and research facilities, with plants in Belgium, Canada, Germany, Italy, and China.

There’s also one in the UK – the Agfa manufacturing facility in Cambridge – a welcome perk from the acquisition of inkjet developer and manufacturer Inca.

Innotech supplies a complete range of flexible wide and grand-format print materials for Agfa printers. Browse our complete range of digital print media here.

Latest blog posts

View all posts

26th July 2024

Marketing Advice for Print Companies

Our Head of Marketing, Kieran Dallow recently shared some marketing advice for print companies with the team at Print [...]

24th July 2024

Roland – Machinery Manufacturer Spotlight

Roland was founded in 1972 in Japan by Ikutaro Kakehashi as a manufacturer of drum machines, synthesisers, and [...]

17th July 2024

SwissQprint – Machinery Manufacturer Spotlight

SwissQprint was founded in 2007 by Reto Eicher, Roland Fetting, and Hansjörg Untersander as a high-end UV inkjet [...]