When backlit banners perform at their optimum, they can produce incredible attention-grabbing displays. However, these banners face significant challenges from environmental factors, particularly moisture. This is where anti-wicking technology comes into play.

In this blog, we’re going to teach you how anti-wicking technology works, why it’s particularly important for backlit banners, and how you can test materials for this essential feature.

How Anti-Wicking Technology Works

Anti-wicking technology involves the application of specialised treatments and coatings to the fibers of the banner material. These treatments prevent water from being absorbed into the material, which helps to maintain its structural and visual integrity. The key components of this technology can include one or both of the following:

Hydrophobic Coatings:

These coatings create a water-repellent surface on the banner material. They prevent moisture from seeping into the fibres by causing water to bead up and roll off the surface.

Fibre Treatment:

Individual fibres of the banner material are treated with anti-wicking agents during the manufacturing process. This treatment makes sure that even if water reaches the fibres, it can’t be absorbed, which prevents any capillary action that could draw moisture into the material.

An example of fibre treated material is the Vistaflex BA510 – Premium PVC Backlit Banner Matt 510g/m2

Why Anti-Wicking Technology is Important

Durability and Longevity:

Moisture can lead to mold and mildew growth, which degrade the material over time. This degradation can cause the banner to become brittle, tear easily, or even fall apart. By preventing moisture absorption, anti-wicking technology extends the lifespan of the banner, making it more durable and cost-effective effective in the long run.

Enhancing Light Diffusion:

Uneven moisture absorption disrupts the uniformity of light diffusion, causing patches of varying brightness which can appear like stains. This uneven lighting reduces the effectiveness of the backlit display, making it look patchy and unprofessional. Anti-wicking properties keep the light diffusion consistent, maintaining the banner’s sharp and attractive appearance.

How to Test for Anti-Wicking Properties

Testing the effectiveness of anti-wicking technology in backlit banner materials involves practical methods that simulate real-world conditions:

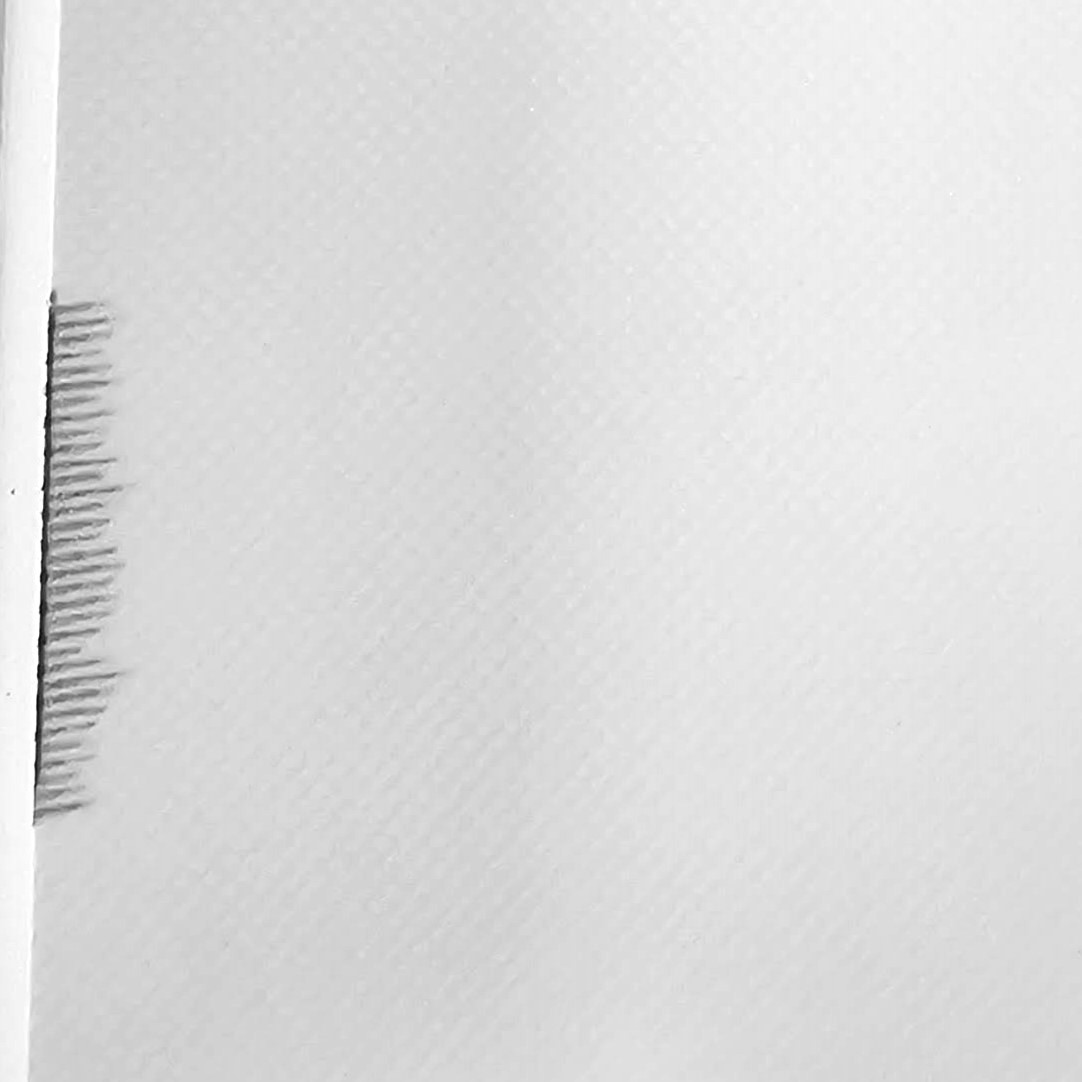

Marker Pen (Capillary Action) Test:

Run the point of a marker pen along the edge of the material. Where the base fabric is not treated the fibres will absorb the ink, allowing you to see it travelling into the material. A properly treated material will not absorb any of the ink, and you will only see a marker line along the edge of the material.

Humidity Chamber Test:

Place a sample of the banner material in a controlled humidity chamber set to high humidity levels for an extended period (e.g., 48-72 hours). Check for changes in the material’s appearance, texture, and performance, particularly focusing on any moisture absorption. A good anti-wicking material will maintain its original properties, showing no signs of moisture-related damage.

By understanding anti-wicking technology, you can make sure that your backlit banners remain visually appealing, durable, and effective, even in challenging environments. Testing for these properties is useful to confirm the material’s suitability for long-term use in various settings.

Latest blog posts

View all posts

16th January 2026

Cold Weather Vinyl Installations: Do’s, Don’ts & Best Practice

Brrrrrrrr… It’s still cold outside! Cold weather can significantly impact vinyl performance if best [...]

5th May 2025

Common Challenges with PVC Free Vinyl and How to Overcome Them

PVC free vinyl is becoming an increasingly popular choice for businesses looking to reduce their environmental impact [...]

15th April 2025

Innotech Expands Range of General Formulation Self-Adhesive Vinyls

After becoming the exclusive UK distributor for General Formulations last year, Innotech are now offering the new GF [...]